- University of Lodz

- Faculty of Chemistry

- Department of Materials Technology and Chemistry

- Experimental techniques and apparatus

- FTIR

FTIR

Nicolet iS50 Spectrophotometer

Basic features:

- Spectral range: 7500-400 cm-1

- Spectral resolution: 0,25 cm-1

- Detectors:

- wide range DTGS, 7500-180 cm-1

- ultrahigh sensitive, low noise, linearized MCT (cooled with LN2), 5000-700 cm-1

The spectrophotometer configuration and additional equipment allow for the examination of the surfaces of various materials, with particular emphasis on thin-film and ultra-thin-film materials. The software included in the kit allows for comprehensive processing, correction and measurement of recorded spectra, including quantitative measurements. We also have the IR-mentor software, supporting the analysis of IR spectra.

We use the following spectroscopic techniques:

- Transmission Spectroscopy

This technique can be used to test samples of solids, liquids and gases. A beam of infrared radiation is passed through the sample and interferes with the reference beam. The resulting spectrum depends on the optical path or thickness of the sample, the absorption coefficient of the sample, the reflectance of the sample, the angle of incidence, the polarization of the incident radiation and, in the case of solid particles, the size and orientation of the particles.

- External Reflection Spectroscopy, Specular Reflection Spectroscopy

In this technique, a beam is reflected from the smooth (mirror) surface of the sample to record its spectrum. It is a non-destructive, non-contact technique. It is particularly useful for measuring coating thickness and refractive index, as well as for recording spectra of thin films on metal substrates.

Specular reflection spectra may differ from transmission spectra in many ways, e.g., bands may be shifted to higher wavenumbers, spectra may reflect dispersion of the refractive index, and spectral contrast may not depend linearly on sample thickness.

Accessories: VeeMax, Refractor

- Attenuated Internal Reflection Spectroscopy, ATR

In ATR, the beam is introduced into a suitable prism at an angle exceeding the critical angle for internal reflection. This causes the evanescent wave to propagate along the reflecting surface. The sample is brought into contact with the reflecting surface. Based on the interaction of the evanescent wave with the sample, a spectrum can be recorded with little or no sample preparation. The ATR technique is non-destructive and can be used on solids, liquids and powders. It was introduced in the 1960s and is now widely used.

For thin films, the ATR spectra are the same as the transmission spectra. For thick layers, absorption bands are more intense for longer wavelengths. As the angle of incidence approaches the critical angle, the bands tend to broaden on the longer wavelength side and the minima are moved toward longer wavelengths (smaller wavenumbers). Dispersive-type spectra are observed very close to and below the critical angle.

Accessories: ATRMax, GATR

- Diffuse Reflection Spectroscopy

The spectra of powders and rough surfaces can be recorded by pointing a beam at them and - using appropriate optics - recording the scattered radiation on their surface.

Since diffuse reflection spectra are the result of light interacting with the sample in every possible way, the spectra may exhibit characteristics of transmission, external reflection, and/or internal reflection. One troublesome feature is the presence of residual radiation bands (reststrahlen bands), the intensity of which can be reduced by diluting the sample. The observed spectra may be further influenced by the particle size of the sample and the angle of incidence of the beam and/or observation.

Accessory: EasyDiff

An important additional equipment of the spectrophotometer are plasma cleaners, which allow the removal of all organic contaminants from the surface of the optical elements (removable) of the device and attachments, which allows for the removal of artifacts that may interfere with the recorded spectra, especially when examining subtle structures occurring in ultra-thin coatings and their modifications.

Accessories

For recording spectra based on specular reflection spectroscopy from the surface of metallic and silicon samples with a variable beam incidence angle in the range of 20-160°. Supports the full spectral range of the instrument. It is adapted to work with a polarizer and, in combination with the MCT detector, allows, similarly to the Rerefractor, to record spectra of ultra-thin layers, which in turn allows us to learn about the structure and chemical changes taking place in the thin and ultra-thin coatings produced and modified by our team..

For recording spectra based on specular reflection spectroscopy from the surface of metallic and silicon samples with a variable beam incidence angle in the range of 20-160°. Supports the full spectral range of the instrument. It is adapted to work with a polarizer and, in combination with the MCT detector, allows, similarly to the Rerefractor, to record spectra of ultra-thin layers, which in turn allows us to learn about the structure and chemical changes taking place in the thin and ultra-thin coatings produced and modified by our team..

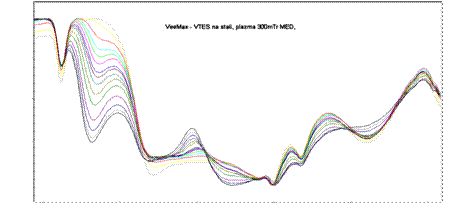

Modification kinetics of a 300 nm thick vinyl silica layer deposited on a silicon substrate in air plasma, recorded using VeeMax.

Modification kinetics of a 300 nm thick vinyl silica layer deposited on a silicon substrate in air plasma, recorded using VeeMax.

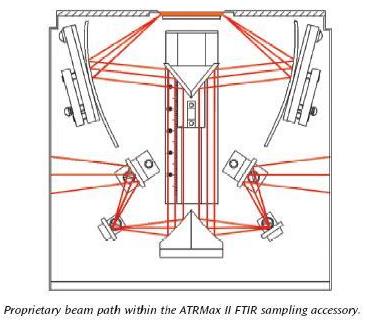

To record spectra, it uses measurement based on the principle of multiple total internal reflection (ATR), with a variable angle of attack of the beam onto the measuring crystal. By using different crystals and adjusting the beam angle, it is possible to penetrate the beam to various depths in the measured material in the range of 1-5 mm. This makes it possible to perform spectral tests in the form of a depth profile for the mentioned depths. The measuring range depends on the type of measuring crystal used.

To record spectra, it uses measurement based on the principle of multiple total internal reflection (ATR), with a variable angle of attack of the beam onto the measuring crystal. By using different crystals and adjusting the beam angle, it is possible to penetrate the beam to various depths in the measured material in the range of 1-5 mm. This makes it possible to perform spectral tests in the form of a depth profile for the mentioned depths. The measuring range depends on the type of measuring crystal used.

Features

-

Selectable angle of incidence - 20 to 70 degrees in one degree increments

-

0.5 to 10 micron depth of penetration - dependent on crystal material, angle of incidence, sample's refractive index and wavelength of IR beam - ideal for depth profiling studies

-

3 to 12 reflections of IR beam - dependent upon angle of incidence - ideal for optimizing ATR sampling methods

-

Flat and trough crystal plates for solids, films, powders and liquid samples

-

Sealed and purgeable optical design to eliminate water vapor and carbon dioxide interferences

Detailed description

The ATRMax is a high throughput, variable angle horizontal ATR accessory developed for use in FTIR spectrometers. The design employs a unique optical layout which enables samples to be analyzed over a range of incident angles (from twenty to seventy degrees). Variable angle of incidence provides experimental control over the depth of penetration of an IR beam into the sample and the number of beam reflections in the ATR crystal, which in turn determines the effective IR beam path length for a given experiment. Adjustable angle of incidence allows immediate optimization of measurements for otherwise difficult to analyze samples. The ATRMax can be used for depth profiling studies where spectral composition can be analyzed relative to depth of penetration as the angle of incidence is changed.

To record spectra, it uses measurement based on the principle of single total internal reflection. The very specific structure of the adapter allows the infrared beam to penetrate only to a very small depth of about a dozen or so nm, while maintaining satisfactory sensitivity of the device. Using the MCT detector, it is possible to record spectra practically from the material surface itself. This is extremely important when testing the modification of material surfaces through chemical reactions or during physicochemical modification, e.g. with low-temperature plasma or UV radiation.

To record spectra, it uses measurement based on the principle of single total internal reflection. The very specific structure of the adapter allows the infrared beam to penetrate only to a very small depth of about a dozen or so nm, while maintaining satisfactory sensitivity of the device. Using the MCT detector, it is possible to record spectra practically from the material surface itself. This is extremely important when testing the modification of material surfaces through chemical reactions or during physicochemical modification, e.g. with low-temperature plasma or UV radiation.

The GATR grazing angle ATR accessory is a revolutionary approach to the analysis of monolayers on semiconductor and metallic substrates. The GATRT is optimized for high sensitivity to these types of samples. Its specially designed pressure applicator is optimized for delivering good contact between the sample and the Ge ATR crystal. The GATRT provides at least an order of magnitude increase in sensitivity relative to grazing angle methods, in addition to the convenience of an easy to use, fully prealigned, horizontal sampling accessory.

Features

-

Convenient horizontal sampling surface.

-

Built-in pressure applicator with slip-clutch for reproducible pressure application.

-

Continuously variable angle from 60ş to 65ş allowing optimization for maximum sensitivity.

-

Anti-backlash mechanism allows for accurate, reproducible angle selection.

-

Mounted Ge ATR crystal.

-

PermaPurgeT for rapid purging of the system.

Applications

-

Analysis of monolayers and adsorbed species on semiconductors and metals.

-

Rapid, repeatable measurements.

Detailed description

The VariGATRT is a single reflection ATR accessory designed for analyzing monolayers and adsorbed species on semiconductor and metallic substrates.

The VariGATRT integrates the theoretical conditions that provide the highest sensitivity to these extremely thin films in a convenient horizontal ATR sampler. The VariGATRT features a Ge ATR crystal for use from 5000 to 650 cm-1. Its incident angle can be varied from 60° to 65°, making it possible to optimize the angle for any given spectrometer and sample. Its specially integrated Slip-Clutch pressure applicator optimizes contact between the sample and the relatively small active portion of the crystal. For greater sensitivity, a polarizer can be added to the VariGATRT and, for more precise measurements of the force applied to the sample by the pressure applicator, a force sensor with digital read-out is available.

For measurements using the diffuse reflection spectroscopy technique - it allows to record spectra from powders and matt surfaces (scattering, not reflective). Supports the full spectral range of the instrument.

For measurements using the diffuse reflection spectroscopy technique - it allows to record spectra from powders and matt surfaces (scattering, not reflective). Supports the full spectral range of the instrument.

Features

-

Pre-aligned optical components for reproducible, high quality data

-

Micrometer controlled sample positioning and focusing

-

High energy throughput providing nanogram sensitivity

-

Precision slide for repeatable sample introduction and efficient collection of background and sample spectra

-

Unique sample preparation and loading kit with two macro cups, two micro cups, spatulas and necessary tools

Detailed description

The PIKE Technologies EasiDiff is an economical, high quality diffuse reflectance accessory designed to analyze a wide variety of solid samples. It is most often used in the analysis of pharmaceuticals, illicit drugs, inorganic solids and minerals, and powdered chemicals.

The EasiDiff reduces the time required to produce an infrared spectrum compared to KBr pellet techniques. Typically, a small amount of sample (about 1%) is mixed and ground with KBr powder and the spectrum is collected.

The EasiDiff employs an elegant, high performance optical design for maximum energy throughput and ease of operation. Optical components critical to achieving this performance are permanently aligned. Focusing is achieved by bringing the sample (not the collection mirror) to the optimum position with a micrometer. A dual position sample holder permits background and sample collection in a simple, two-step process. A spectrum of papaverine hydrochloride (about 1% in KBr powder) was collected using the PIKE Technologies EasiDiff diffuse reflectance accessory.

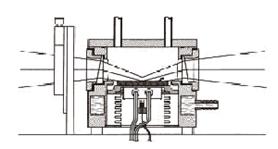

Accessory in the form of a pressure-vacuum reaction chamber. The spectrum is recorded based on the principle of specular reflection spectroscopy from the sample surface, which can be precisely heated to a temperature of 500oC, in a controlled atmosphere, under a pressure of up to 2 atm. It supports the full spectral range of the instrument (it has interchangeable windows). It allows to record spectra of substances deposited on metal and silicon surfaces while heating them to 500oC, in a controlled atmosphere. This makes it possible to observe the thermal durability of thin coatings applied to the above substrates. After configuring the spectrophotometer using a polarizer and an MCT detector, it is possible to observe the spectra of ultrathin coatings with thicknesses of several nanometers and thicker.

Accessory in the form of a pressure-vacuum reaction chamber. The spectrum is recorded based on the principle of specular reflection spectroscopy from the sample surface, which can be precisely heated to a temperature of 500oC, in a controlled atmosphere, under a pressure of up to 2 atm. It supports the full spectral range of the instrument (it has interchangeable windows). It allows to record spectra of substances deposited on metal and silicon surfaces while heating them to 500oC, in a controlled atmosphere. This makes it possible to observe the thermal durability of thin coatings applied to the above substrates. After configuring the spectrophotometer using a polarizer and an MCT detector, it is possible to observe the spectra of ultrathin coatings with thicknesses of several nanometers and thicker.

Diagram of the accessory

Spectrum of a monolayer of decanethiol on a gold surface (red - gas phase standard, blue - SAM monolayer of decanethiol on a gold surface).

The Refractor Reactor is a valuable tool for grazing angle FT-IR studies of reactions on metal surfaces and on thin films on metal substrates. Samples can be heated to 400°C and pressurized up to 2 ATM.

Features

-

75° grazing incident angle for high sensitivity to films on metallic substrates

-

Incorporates two Supercharged ZnSe wedged windows to refract the beam to and from the sample

-

Ideal for samples up to 1" x 2" x 1/8"

-

Heatable up to 400°C (under vacuum) for studying high temperature reactions

-

Operable at pressures from 10-4 torr to 2 ATM

-

Manufactured from chemically resistant 316 stainless steel

-

High efficiency

-

Designed for in-line use of a wire grid polarizer

Applications

Perfect for studying reaction on metal surfaces and on thin films on metal substrates.

Detailed description

The Reactor Refractor is a reaction chamber for in-line grazing incidence studies. It is ideal for recording spectra of thin films on metal substrates. The angle of incidence is fixed at 75 degrees and can accommodate samples up to 1"x2"x0,05" thick. It can be heated up to 400°C under vacuum, evacuated to 10-4 torr, and pressurized up to 2 ATM with the standard ZnSe windows. Excellent spectral contrast results. Conventional in-line grazing incidence attachments have a significant drawback. The short plane mirrors employed do not totally intercept the beam of the spectrometer, resulting in a significant loss in optical throughput. In the Refractor, these losses do not occur, since the optical beam is deflected (15°) to and from the sample via wedged (10°) ZnSe windows. The Refractor Reactor has two ports for flowing reactant over the sample, evacuating the sample, and pressurizing the sample with a reactant. Heating cartridges are imbedded below the sample and two thermocouples are supplied to measure the sample and heater temperatures. For precise temperature control, the heater and thermocouples is connected to an Automatic Temperature Controller (Harrick's ATC-002)